The Best Motion Hardware for Reducing Risk

Motion System

- Controller can be ordered in configurations from 2 to 16 axes with mixed motor types

- Axes can be organized in multiple concurrent axis groups for flexible configuration

- Multiple controllers can communicate in star and ring configurations using RS232, RS485, or Fiber

- Velocity profiles include native trapezoidal and application-level s-curve and custom shapes

- Samples rates 500 Hz to 8 kHz providing high performance

- Native Interpolation Modes include linear, circular, helical, and curves composed of concatenated lines and arcs

- Application level Interpolation can be described in resident programs and run at the sample rate

- Coordination Modes include electronic gearing, camming, tangent, encoder-replaces-time, kinematics, motion superposition, and coordination tailoring

- High speed position capture supports high speed registration

- High speed position compare supports on-the-fly output operations in relationship to motion

Mixed Motor and Encoder Types

- Signal support for analog servo, digital servo, stepper motors

- Step rates and encoder count rates to 2 MHz

- Stepper Drive support through option slot for 1,2,3, or 4 internal microstepping drives

- Quadrature and BiSS encoder support

Onboard Language

- Graphical Block Interface or Text Programming Interface

- Programs cross-compile to native object code for very high performance

- Data structures and object oriented design support

- 64 concurrent tasks supported each running every controller sample

IO System

- (18) Isolated Digital Inputs, 5-24 volts

- (8) 2 amp 24 volt sourcing outputs with recirculating diodes for inductive loads

- (48) TTL IO points configurable as inputs or outputs on an individual bit basis. Compatible with Opto22 series D racks

- Optical Isolation between controller logic power, 24 volt inputs, 24 volt outputs, servo command signals, and servo enables

- Dual digital and analog watchdog safety systems suppresses motion signals at the hardware level in the event of a software failures, firmware failure, or dedicated EStop event

- (8) analog inputs on TTL inputs 1 through 8 for signals in the 0V-5V range

Processor

- 800 Mhz x86 processor

- 80 bit floating point hardware supporting transcendentals for kinematic applications

Command Signals

- Differential drivers for step/direction signals

- Differential receivers for encoders

- Optically isolated servo enable signals can source or sink

- Stepper enable provides open collector to ground

Communication

- USB connects Servo Application Workbench software to provide development and run-time view of controller during operation

- Ethernet server port provides host connection access for industrial HMI or network

- (2) RS232 ports

- (2) RS485 ports

- Fiber interface supports ring topology for inter-controller communication

Option Slot

- Additional RS232 ports

- Additional Axes

- Internal Drives

- Additional analog inputs and outputs

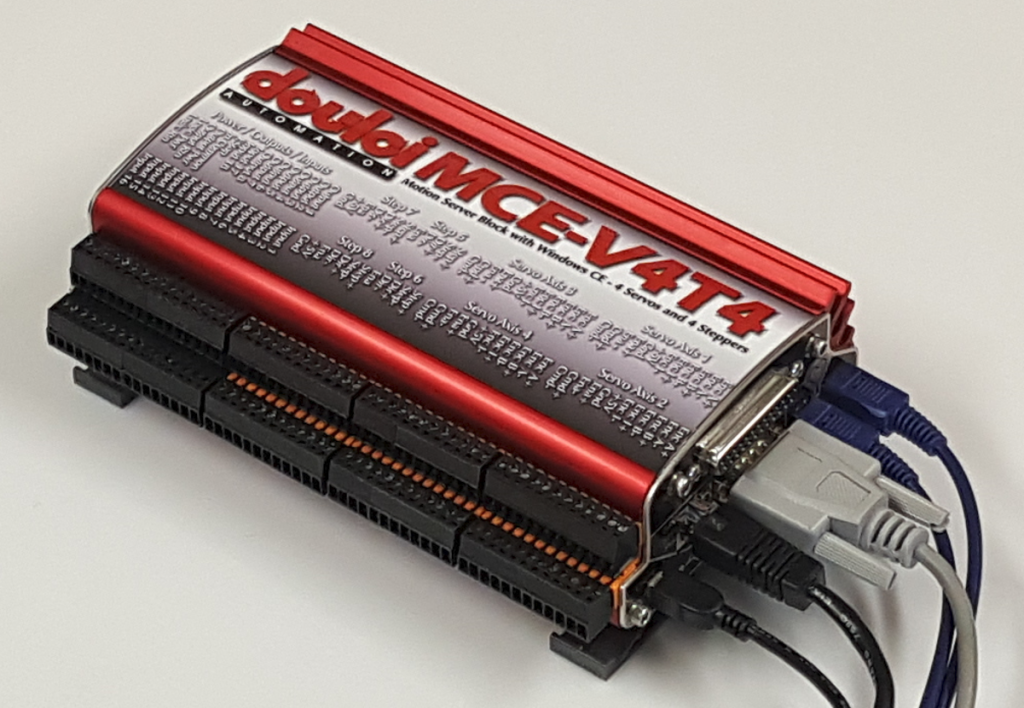

Enclosure

- Sturdy extruded aluminum enclosure suitable for an industrial environment

- DIN rail mounting feet

- Detachable 3.5mm screw terminal connectors supports field swap without rewiring

- Passive heat sink fins manage heat without active fan that can wear out

- 7.75″ x 4.75″ x 2.75″